When choosing between sodium lignosulfonate (wood sodium) and calcium lignosulfonate (wood calcium), you are weighing two industrial chemicals with similar properties but key differences. Both substances are widely used as dispersants, binders, and chelating agents, but their performance in specific applications varies due to the primary metal ions they carry. Understanding these differences is crucial for making the right choice.

Core Difference: Ions Determine Performance

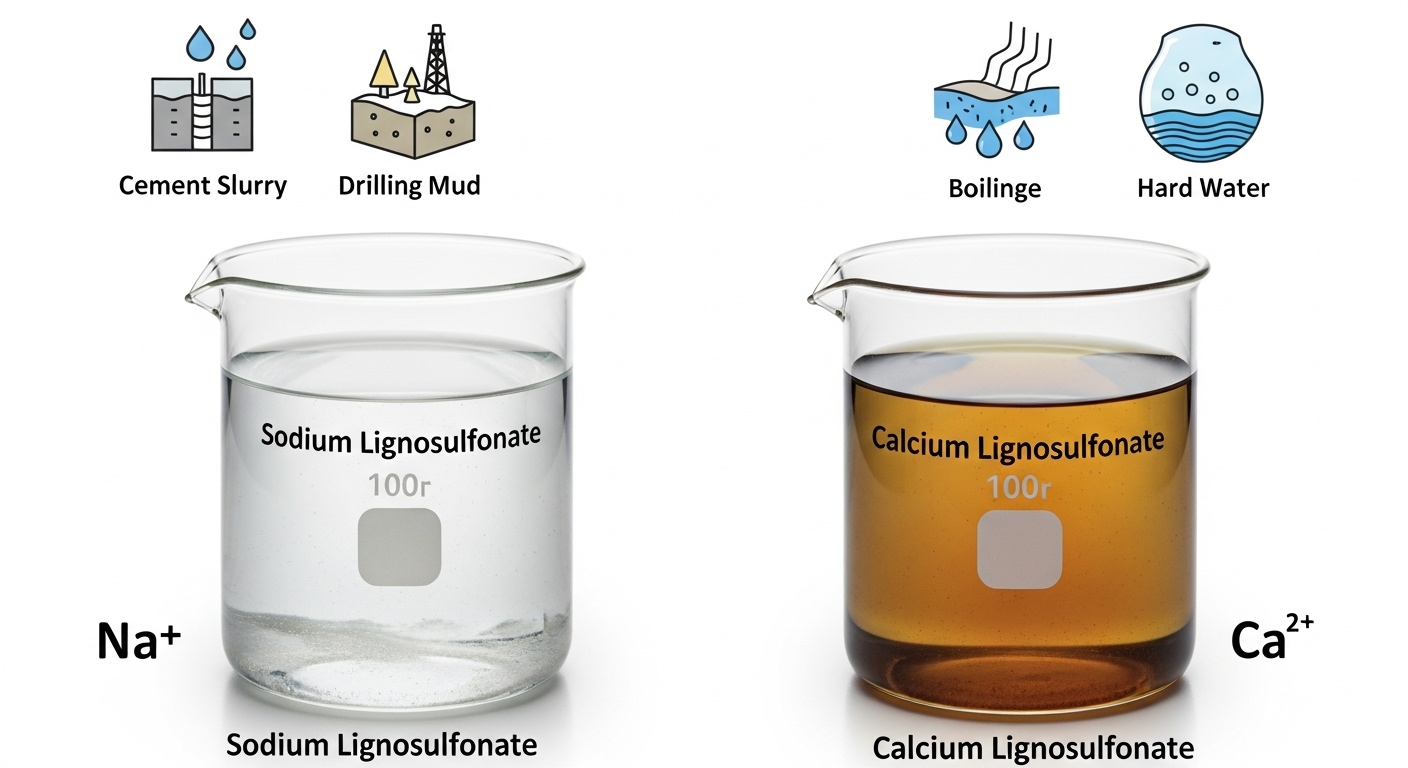

The fundamental distinction between sodium lignosulfonate (primarily containing sodium ions Na+) and calcium lignosulfonate (primarily containing calcium ions Ca²⁺) lies in their ionic composition. This difference impacts their solubility in water, surface activity, and sensitivity to other ions.

Solubility and Activity: Generally, sodium lignosulfonate exhibits superior water solubility and typically demonstrates higher surface activity. This enables it to provide stable and efficient dispersion effects in many routine applications.

Salt/Calcium Resistance: Calcium lignosulfonate excels in environmental adaptability. It exhibits greater resistance to water bodies with high salinity or elevated calcium ion concentrations. In environments containing significant hard water ions (such as calcium and magnesium ions) or high salinity, sodium lignosulfonate may experience performance degradation or even flocculation, whereas calcium lignosulfonate maintains relative stability.

Application Scenario Selection Guide

Your final choice should be strictly based on your specific operating environment and performance requirements:

Select sodium lignosulfonate (Na-Lignosulfonate) if:

Water quality is good and stable: Your project uses freshwater or soft water without significant interfering ions.

Cost-effectiveness is prioritized: Na-Lignosulfonate is typically the more economical choice while meeting performance requirements.

Conventional applications: Suitable for water-coal slurry additives, asphalt emulsifiers, and most standard cement superplasticizer uses.

Select calcium lignosulfonate (calcium lignosulfonate) if:

Harsh environments (high salt, high calcium, high temperature): You require operation in seawater, hard water, or complex environments containing specific mud types. For example, in oilfield drilling, calcium lignosulfonate is the preferred mud diluent due to its robust salt resistance and high-temperature tolerance.

Superior anti-flocculation stability is required: Calcium lignosulfonate offers greater assurance in formulations demanding extreme stability. Specific material binders: It is widely used as a high-performance binder in refractory materials, ceramic bodies, and carbon black production.

There is no universally “better” product, only the one “better suited” for specific applications. Sodium lignosulfonate is a versatile and economical general-purpose solution; calcium lignosulfonate is a specialized solution optimized for harsh environments and specific requirements.

The most prudent approach is to conduct detailed product testing and performance evaluations based on your project's specific water quality, temperature, salinity requirements, and budget constraints to ensure you make the optimal choice best suited to your needs.